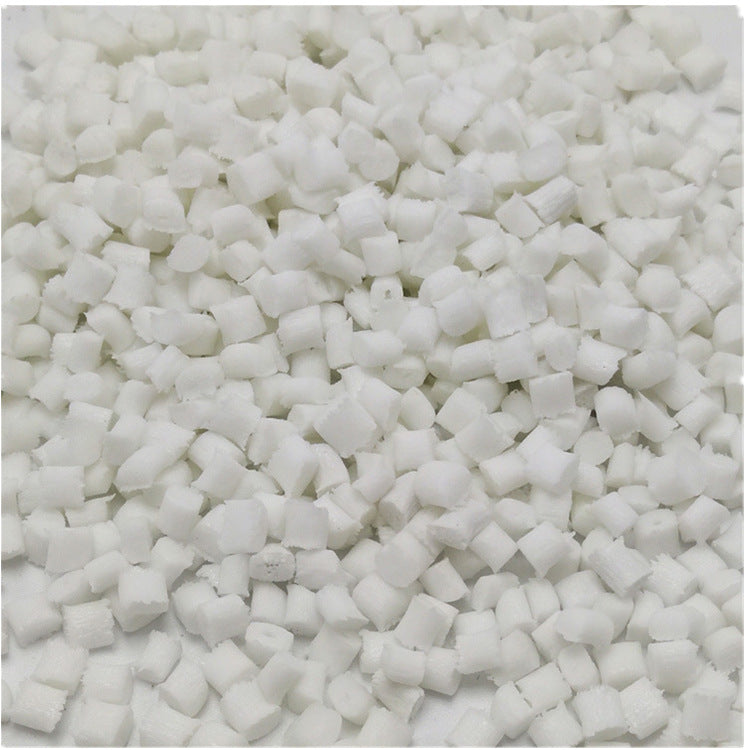

The Mystery of PA6 Plastic Particles

PA6, also known as nylon 6, polyamide 6, or nylon 6, is a common engineering plastic that is thermoplastic. It is known for its excellent physical properties, chemical stability and processing properties, and is widely used in many fields. Today, let's take a closer look at all aspects of PA6.

1. Basic introduction of PA6 🔍

PA6 is a thermoplastic with excellent mechanical properties such as high strength, high toughness and high rigidity. Its chemical and physical properties are similar to PA66, but the melting point is lower and the process temperature range is wider. The impact resistance and solubility of PA6 is better than that of PA66, but the hygroscopicity is stronger.

2. Features of PA6 🌟

2.1 Physical properties 💪

PA6 is known for its high strength, toughness and wear resistance, making it an ideal material for the manufacture of various parts and components, especially in complex mechanical applications.

2.2 Chemical stability 🌀

PA6 has good tolerance to common solvents, acids, alkalis and other chemicals and is not susceptible to damage or corrosion. This makes PA6 widely used in chemical, aviation and medical fields.

2.3 Processing properties 🛠️

PA6 is a thermoplastic that can be made into parts of different shapes and sizes by heating and plastic deformation. Its good fluidity makes it excellent in various processes such as injection molding, extrusion molding, blow molding and extrusion molding.

3. Injection molding process of PA6 🔩

3.1 Melting temperature: usually between 230~280 ° C, for enhanced varieties is 250~280 ° C.

3.2 Drying treatment: Because PA6 is easy to absorb water, it needs to be dried before processing. If the material is supplied in waterproof packaging, keep the container airtight. When the humidity is greater than 0.2%, it is recommended to dry in hot air above 80 ° C for 16 hours. If the material is exposed for more than 8 hours, it is recommended to vacuum dry at 105 ° C for more than 8 hours.

3.3 Mold temperature: It is recommended that the mold temperature is 80-90℃, which significantly affects the crystallinity, and then affects the mechanical characteristics of the plastic parts. Crystallinity is important for structural components. For thin-walled and long process plastic parts, it is recommended to use a higher mold temperature. Increasing the mold temperature can improve the stiffness of the plastic parts, but reduce the toughness. If the wall thickness is greater than 3mm, it is recommended to use a low temperature mold of 20-40℃. For reinforcement materials, the mold temperature should be greater than 80 ° C.

3.4 Injection pressure: generally between 750-1250bar.

4. PA6 application field 🌍

4.1 Automobile manufacturing 🚗

PA6 has a wide range of applications in automotive manufacturing, such as manufacturing parts, airbag cloth, cylinder head and cylinder block. Its wear resistance and high temperature resistance enable it to withstand complex mechanical stresses and the effects of high temperature environments.

4.2 Electronic and electrical 💻

PA6 is used in the manufacture of electrical sockets, wire and cable and electronic equipment enclosures. Its good physical and chemical properties provide good electrical insulation and anti-aging ability.

4.3 Sporting goods 🏂

PA6 is also widely used in the field of sporting goods, such as skis, skateboards, wading shoes and treadmills. Its strength, toughness and wear resistance make it able to withstand complex mechanical stresses and various harsh environments.